Below is a guide which will help you decide which

FormFutura 3D Filament would fit best for your project.

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

EasyFil™ PLA is a high-end “easy to use” 3D printer filament, which is slightly modified with an impact modifier making the filament tougher, slightly softer, less rigid, much longer preservable and easy to print at relatively low temperatures.

Another great advantage of EasyFil™ PLA – compared to regular PLA – is EasyFil™’s low shrinkage factor, which makes EasyFil™ PLA nearly warp-free and therefore EasyFil™ PLA will not deform after cooling. Due to its low tendency to warp EasyFil™ PLA can be printed without a heated print bed. If your printer is however equipped with a heated print bed we recommend to set your heat bed temperature to ± 35° to 60°C.

Next to its “easy to use” features, our Formfutura EasyFil™ filament range has an excellent roundness and very tight diameter and roundness tolerances, which makes this filament a perfect match with all common desktop 3D printers. Printing with EasyFil™ PLA 3D printer filament will go very smoothly with basically all FFF/FDM technology based desktop 3D printers

EasyFil™ PLA - 1.75mm - Click Here

EasyFil™ PLA - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

EasyFil™ ABS is a high-end “easy to use” 3D printer filament. Our EasyFil™ ABS is not like regular ABS, because EasyFil™ ABS has a very high impact-resistance, is extra strong, and above all is “easy to print” because of its limited warping!

It is recommended to set your heated print bed ± 90-110˚C when printing with EasyFil™ ABS.

Next to its “easy to use” features, our Formfutura EasyFil™ filament range has an excellent roundness and very tight diameter and ovalidity tolerances, which makes this filament a perfect match with all common desktop 3D printers. Printing with EasyFil™ ABS 3D printer filament will go very smoothly with basically all FFF/FDM technology based desktop 3D printers

EasyFil™ ABS - 1.75mm - Click Here

EasyFil™ ABS - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

EasyWood™ looks, feels and smells like real wood. EasyWood™ is a unique mixture of 40% grinded wood particles in combination with the modified and proven easy-to-print binding polymers used for our EasyFil™ filaments. This extraordinary blend has resulted in a high-end and unsurpassed “easy to print” wooden filament.

Because of its low shrinkage factor, EasyWood™ is nearly warp-free and therefore EasyWood™ will not deform after cooling. Due to its low tendency to warp EasyWood™ can be printed without a heated print bed. If your printer is however equipped with a heated print bed we recommend to set your heat bed temperature to ± 35° to 60°C.

EasyWood™ prints best at a printing temperature range within 200°C and 240°C. Printing with EasyWood™ is remarkable easy, as it is a very easy to process material and an excellent first layer adhesion can be obtained by printing at various undergrounds without needing a heated print bed.

Next to its “easy to use” features, our Formfutura EasyWood™ filament range has an excellent roundness and very tight diameter tolerances, which makes this filament a perfect match with all common desktop 3D printers. Printing with EasyWood™ 3D printer filament will go very smoothly with basically all FFF/FDM technology based desktop 3D printers.

EasyWood™ - 1.75mm - Click Here

EasyWood™ - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

HDglass™ is our amorphous and high strength modified PETG compounded 3D printer filament range. HD stands for “Heavy Duty”, as HDglass™ has excellent properties when it comes to strength, toughness and temperature resistance for same like materials. Next to being heavy duty, the HDglass™ See Through and Clear-range has a very impressive transparency as it is an amorphous filament, which lets 90% of the visible light pass through its fibre and has less than 1% haze. With HDglass™ See Through filaments you are now able to get the closest approximate to glass-like results for 3D printed objects.

HDglass™ - 1.75mm - Click Here

HDglass™ - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

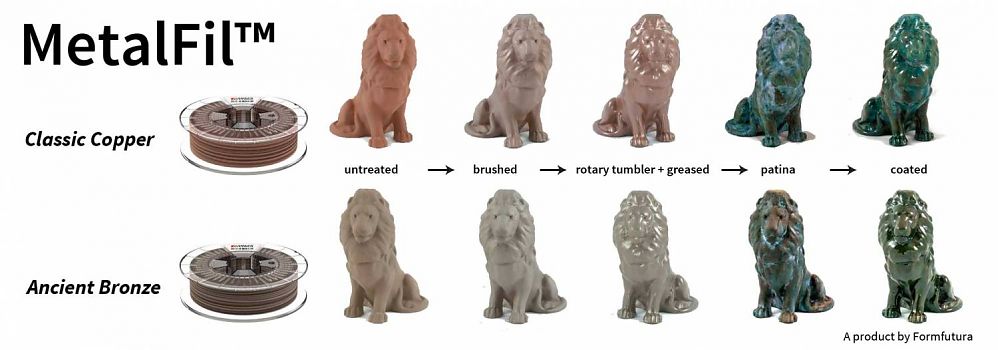

MetalFil™ - Classic Copper is an incredible new metal-filled PLA-based filament with approximately 80% of gravimetric copper filling. This incredible high filling with copper powders enables every FDM 3D printer user to 3D print copper objects which are almost indistinguishable from genuine copper.

The extremely high copper filling in MetalFil™ - Classic Copper has resulted in an incredibly heavy filament with a density of 3.5 g/cc. Unlike other metal-filled filaments MetalFil™ - Classic Copper can be printed on full metal, PEEK, and PFTE hotends and can perfectly be printed with 0.4mm nozzles. This makes MetalFil™ - Classic Copper basically perfectly suitable for all FDM 3D printers. You can even enable retraction settings on both direct drive extruders, as well as on Bowden style extruders, which is a truly unique feature for a metal-filled filament.

MetalFil™ - Classic Copper is a very easy to print material and ensures stable 3D printing results on basically all types of FDM 3D printers. This makes MetalFil™ - Classic Copper a perfectly suitable filament for beginners and intermediate 3D printing enthusiasts, whereas other metal-filled filaments are only suitable for experienced users.

MetalFil™ Classic Copper - 1.75mm - Click Here

MetalFill™ Classic Copper - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

MetalFil™ - Ancient Bronze is an incredible new metal-filled PLA-based filament with approximately 80% of gravimetric bronze filling. This incredible high filling with bronze powders enables every FDM 3D printer user to 3D print bronze objects which are almost indistinguishable from genuine bronze.

The extremely high bronze filling of MetalFil™ - Ancient Bronze has resulted in an incredibly heavy filament with a density of 3.4 g/cc. Unlike other metal-filled filaments MetalFil™ - Ancient Bronze can be printed on full metal, PEEK, and PFTE hotends and can perfectly be printed with 0.4mm nozzles. This makes MetalFil™ - Ancient Bronze basically perfectly suitable for all FDM 3D printers. You can even enable retraction settings on both direct drive extruders, as well as on Bowden style extruders, which is a truly unique feature for a metal-filled filament.

MetalFil™ - Ancient Bronze is a very easy to print material and ensures stable 3D printing results on basically all types of FDM 3D printers. This makes MetalFil™ - Ancient Bronze a perfectly suitable filament for beginners and intermediate 3D printing enthusiasts, whereas other metal-filled filaments are only suitable for experienced users.

MetalFil™ Ancient Bronze - 1.75mm - Click Here

MetalFill™ Ancient Bronze - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

CarbonFil™ is a light-weight and incredibly stiff carbon fibre reinforced filament. Our CarbonFil™ filament is based upon a unique blend of our HDglass™ compound reinforced with 20% ultra-light and relatively long stringer carbon fibres, which has resulted in an exceptionally stiff carbon fibre 3D printer filament.

By making use of ultra-lightweight and relatively long carbon fibre stringers we have managed to make our CarbonFil™ twice as stiff as our HDglass™ compound and yet we still managed to increase its impact strength with more than 10%. Usually an upturn in a material’s stiffness will have a downturn on its impact strength. With CarbonFil™ we managed to increase both these parameters and by that it can truly be called a tough material.

Adding such a relatively high percentage of 20% long stringer carbon fibres into our CarbonFil™ compound also has resulted in a relatively high heat deflection temperature of 85°C and very good dimensional stability properties.

The CarbonFil™ compound combines quite a few unique properties into a 3D printer filament and still one of the most important properties hasn’t been named yet, namely its printer friendliness. CarbonFil™ outperforms any other carbon filament when it comes to printability of the filament.

Printing with CarbonFil™ filament is truly very easy and comfortable as it is warp-free, can be printed without a heated bed, has a great thermal stability, an excellent flowing behaviour and a superb first- and interlayer adhesion and does not produce any odors during 3D printing.

CarbonFil™ filament and its printed objects have a stunning matt charcoal black carbon colour, feel and look and prints best at a printing temperature range within 230°C and 265°C. CarbonFil™ can be printed without a heat bed and sticks extremely well to EuroCel Blue Masking Tape.

CarbonFil™ unique features

- Extremely stiff

- Incredible carbon look and feel

- Very easy to print

- Warp-free

- Light-weight

- Great impact resistance

- Excellent first- and interlayer adhesion

- Great dimensional stability

Above set of unique features opens a whole new field of application for desktop 3D printing. Light-weight, stiffness, dimensional stability and an awesome carbon appearance are an assurance for applying desktop 3D printing to new fields of application in for instance the automotive and aerospace industry. What about printing your own drone, parts for your motorbike, or car parts?

CarbonFil™ has an excellent roundness and very tight diameter tolerances, which makes this filament a perfect match with all common desktop 3D printers. Printing with CarbonFil™ 3D printer filament will go very smoothly with basically all FFF/FDM technology based desktop 3D printers, such as:

- Ultimaker

- RepRap (Mendel, Huxley, Prusa)

- WASP

- Sharebot

- Solidoodle

- MakerBot (Replicator, Replicator 2, Replicator 2X)

- Leapfrog

- UP! Plus, Up! Mini

- AND MANY MORE....!

CarbonFil™ - 1.75mm - Click Here

CarbonFil™ - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

EasyCork™ is a lightweight cork-filled PLA-based filament which is gravimetrically filled with approximately 30% cork fibres. The gravimetric filling with relatively lightweight cork fibres means that EasyCork™ has extremely high volumetric cork filling properties, allowing you to 3D print beautiful objects with great cork-like aesthetics and cork-like properties such as being lightweight and impact resistant.

EasyCork™ is available in a natural dark cork and light cork variant. Both colours are based on natural cork fillers which will give your printed object a “living” appearance with very subtle natural linings which can be reinforced by playing around with extrusion temperature variations during your 3D print.

EasyCork™ is a very easy to print material as it is based on our EasyFil™ PLA compound and the 30% gravimetrical filling with cork fibres make the filament absolutely warp-free. EasyCork™ has an excellent filament flowing behaviour allowing you to 3D print cork-like objects with high printing speeds. Certain geometric shapes can even be 3D printed with extremely high speeds.

EasyCork™ - 1.75mm - Click Here

EasyCork™ - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

ApolloX™ is a professional high-performance engineering filament, which is based on an uniquely industrial-grade modified ASA (Acrylonitrile Styrene Acrylate) compound. ApolloX™ has been modified to have great thermal stability, improved filament flowing behavior, zero-warping and flawless first- and interlayer adhesion allowing you to 3D print objects with an almost injection molding precision.

ApolloX™ is UV and weather resistant and by that ensuring great color stability – combined with high strength and heat resistant properties – which makes ApolloX™ a perfect engineering filament for outdoor and automotive applications.

With ApolloX™ we bring the unique thermoplastic properties of ASA to the scope of FDM 3D printing and because of its FDM-optimization it is perfectly suitable for large scale prints.

With its below displayed unique set of characteristics ApolloX™ is a true asset to our Formfutura product portfolio.

- UV & weather resistant

- Extremely high printing precision

- FDM-optimized

- Excellent adhesion to heated glass plate, Kapton tape, PET tape and EasyPad™

- Warp-free

- Perfect inter-layer adhesion

- Great thermal stability and filament flowing behavior

- FDA food and drink contact compliant

ApolloX™ has an excellent roundness and very tight diameter tolerances, which makes this filament a perfect match with all common desktop 3D printers. Printing with ApolloX™ 3D printer filament will go very smoothly with basically all FFF/FDM technology based desktop 3D printers.

ApolloX™ - 1.75mm - Click Here

ApolloX™ - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

EasyFil™ HIPS will be a true competitor for mass mainstream 3D printing materials, such as PLA and ABS. With EasyFil™ HIPS being positioned as a new mainstream 3D printer filament, it will now bring a special 3D print material to the ordinary. You will now be able to print PolyStyrene objects just as easy as PLA, or ABS objects!

EasyFil™ HIPS is a is thermoplastic polymer filament known as High Impact PolyStyrene, which is especially designed for 3D printing PolyStyrene objects. EasyFil™ HIPS distinguishes itself from “normal” HIPS filaments by being slightly softer and more flexible – in combination with very limited warping, having an excellent thermal stability and 3D print flowing behaviour – resulting in a truly “easy to print” HIPS 3D printer filament and a true asset to our EasyFil™ filament range.

With EasyFil™ HIPS you will be able to 3D print PolyStyrene objects with fine detail in a beautiful matt colored finish.

EasyFil™ HIPS 3D printed parts are very lightweight and can very easily be glued together with a variety of adhesives, such as HIPS styrene glues, epoxy based adhesives, superglues and also with contact adhesives. These specific characteristics of EasyFil™ HIPS, make our EasyFil™ HIPS an ideal filament for applications like model building, or for gluing modular prints.

PolyStyrene is a thermoplastic which is very chemically inert, being resistant to acids and bases. Because of its resilience and inertness, PolyStyrene is one of the most widely used thermoplastic polymers in the world. PolyStyrene is for instance extensively being used in the food packaging industry, but also for the production of e.g. disposable plastic cutlery/dinnerware and CD/DVD jewel cases.

EasyFil™ HIPS has outstanding characteristics with respect to hygiene, strength and heat resistance and it prints really smoothly. 3D printed objects with EasyFil™ HIPS can be sanded, primed and if needed painted with acrylic afterwards. By giving your EasyFil™ HIPS printed object an acetone vapor smoothing treatment you will be able to create a really smooth and shiny surface. Your FFF/FDM 3D printed object will almost look like an injection moulded model.

EasyFil™ HIPS is available in various vivid colors and prints best at approximately 235°C. It is recommended to set your heated print bed temperature at approximately 90-110°C.

EasyFil™ HIPS has an excellent roundness and very tight diameter tolerances, which makes this filament a perfect match with all common desktop 3D printers. Printing with EasyFil™ HIPS 3D printer filament will go very smoothly with basically all FFF/FDM technology based desktop 3D printers, such as:

• Ultimaker

• RepRap (Mendel, Huxley, Prusa)

• Solidoodle

• MakerBot (Replicator, Replicator 2, Replicator 2X)

• Leapfrog

• UP! Plus, Up! Mini

• AND MANY MORE....!

Our EasyFil™ HIPS does not contain any hazourdas, or chemical substances. In fact, all our EasyFil™ HIPS filaments are RoHS certified and REACH compliant.

EasyFil™ HIPS - 1.75mm - Click Here

EasyFil™ HIPS - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

TitanX™ is a revolutionary new high-performance and FDM-optimized engineering filament. TitanX™ is the evolution of ABS into a warp-free filament extremely suitable for 3D printing large scale and high precision engineering objects. With TitanX™ we present an industrial-grade ABS-type of 3D printer filament with unsurpassed mechanical properties which is uniquely modified with its FDM-optimization technology.

TitanX™ is truly FDM-optimized as it has zero warping, a perfect interlayer adhesion and can be printed directly on a heated glass plate without any adhesives or tapes to be used. This FDM-optimization combined with a perfect filament flowing behavior, thermal stability and far above average impact resistance make TitanX™ a perfect filament for 3D printing large scale engineering objects with a remarkable fine detail.

Dependent on the size and design of the printed object, TitanX™ can be printed at elevated printing speeds.

With its below displayed unique set of characteristics TitanX™ is a true asset to our Formfutura product portfolio.

- FDM-optimized

- Excellent adhesion to heated glass plate, Kapton tape, PET tape and EasyPad™

- Warp-free

- Perfect inter-layer adhesion

- Greatly improved mechanical properties

- High impact resistance

- Great thermal stability and filament flowing behavior

- FDA food and drink contact compliant

TitanX™ has an excellent roundness and very tight diameter tolerances, which makes this filament a perfect match with all common desktop 3D printers. Printing with Titanx™ 3D printer filament will go very smoothly with basically all FFF/FDM technology based desktop 3D printers.

TitanX™ - 1.75mm - Click Here

TitanX™ - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

You are now also able to 3D print opaque coloured ABS objects without warping and having the unpleasant smell of ABS during 3D printing!

ClearScent™ ABS is nearly warp-free, has an excellent thermal stability and its 3D printing flowing behaviour is fine-tuned for optimal 3D printing results. Above features combined with a superb first- and interlayer adhesion ensure that ClearScent™ ABS printed parts will really look amazing.

ClearScent™ ABS has a good chemical resistance and prints really smoothly. ClearScent™ ABS is soluble in Acetone , TetraHydroFuran (THF) and other Analogous Solvents. By being soluble in these solvents, ClearScent™ ABS printed objects can for instance perfectly be treated with an Acetone vapor smoothing treatment. By giving your ClearScent™ ABS printed object an acetone vapor smoothing treatment you will be able to create a really smooth and even more shiny surface. Your FFF/FDM 3D printed object will almost look like an injection molded model.

ClearScent™ ABS is available in transparent clear, various vivid semi-transparent colours and now also in opaque colours. ClearScent™ ABS can best be printed within a temperature range between 220-260°C. It is recommended to set your heated print bed temperature at approximately 90-100°C.

ClearScent™ ABS has an excellent roundness and very tight diameter tolerances, which makes this filament a perfect match with all common desktop 3D printers. Printing with ClearScent™ ABS 3D printer filament will go very smoothly with basically all FFF/FDM technology based desktop 3D printers.

Our ClearScent™ ABS does not contain any hazardous, or chemical substances. In fact, all our ClearScent™ ABS filaments are RoHS certified, REACH compliant and even are FDA food and drink contact approved.

ClearScent™ ABS unique features:

- Odorless processing/printing

- Nearly warp-free

- Transparent

- FDA food and drink contact approved

- Easy to process

- High impact strength

- Good chemical resistance

ClearScent™ ABS - 1.75mm - Click Here

ClearScent™ ABS - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

Atlas Support™ is the next generation in water-soluble support materials for FDM 3D printing. Atlas Support™ is the result of extensive research to PVA improvement which has resulted in an unique formulation where numerous PVA grades have been blended into one superior water soluble support material.

Atlas Support™ has a far more improved thermal stability compared to "normal" PVA and by that ensures a much more stable dual extrusion printing process. Clogged nozzles because of dual extrusion printing with PVA now belong to past tense.

Atlas Support™ has great bonding to a wide variety of materials, such as PLA, ABS, PETG, ASA, HIPS, FlexiFil, etc.. and last, but definitely not least, is much less sensitive to degradation by humidity. This makes Atlas Support™ much better and longer preservable and its unique set of characteristics really take dual extrusion FDM 3D printing to the next level.

Atlas Support™ is soluble in cold water and is 100% biodegradable once dissolved in water.

With its below displayed unique set of characteristics Atlas Support™ will take dual extrusion 3D printing to the next level.

- Improved thermal stability

- Excellent solubility in cold water

- Great bonding to PLA, ABS, PETG, ASA, HIPS, FlexiFil™, etc..

- Biodegradable

- Odorless processing

Atlas Support™ has an excellent roundness and very tight diameter tolerances, which makes this filament a perfect match with all common desktop 3D printers. Printing with Atlas Support™ 3D printer filament will go very smoothly with basically all FFF/FDM technology based desktop 3D printers

Atlas Support™ - 1.75mm - Click Here

Atlas Support™ - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

ABSpro™ is a heavy duty filament with excellent mechanical properties for more professional usage.

Our ABSpro™ compound is a unique mixture of ABS reinforced with Styrene Maleic Anhydride and PolyCarbonate making an incredibly strong and even more impact resistant filament which enables you to make ABS prints with a remarkable fine detail.

ABSpro™ is much stronger than any other ABS type of 3D printer filament and allows you to print in such a high detail that it outperforms any other ABS type of filament when it comes to printing precision. ABSpro™ even outperforms most PLA type of filaments when it comes to printing fine-detailed prints.

ABSpro™ requires a printing temperature of 250-280°C.

When printing with ABSpro™ it is important to set your print bed temperature to its max level. A print bed temperature of 110 -120°C (or even higher) is recommended. If possible we also advice to print ABSpro™ in a controlled temperature area/box in order to keep temperature fluctuations to a minimum. Because of ABSpro™’ incredible hardness and impact resistance it is more vulnerable to warping caused by temperature fluctuations and therefore it is best to keep the printing environment settings as constant as possible.

When printing with ABSpro™ you might need to tweak around a bit to obtain a good first layer adhesion. It will definitely help to add a strong adhesive slurry like ABS juice or adhesive spray like dimafix to your print bed.

ABSpro™ has an excellent roundness and very tight diameter tolerances, which makes this filament a perfect match with all common desktop 3D printers. ABSpro™ is especially developed for FDM/FFF technology based 3D printers and will basically work with any desktop 3D printer.

Our ABSpro™ does not contain any hazardous, or chemical substances. In fact, all our ABSpro™ filaments are RoHS certified, REACH compliant and even are FDA food and drink contact approved.

ABSpro™ - 1.75mm - Click Here

ABSpro™ - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here

Crystal Flex™ is a heavy duty, translucent and yet flexible filament. Crystal Flex™’s transparency is being described as “plexiglass-like” as apparently Crystal Flex™ will let 91% of visible light pass through its fibre. Crystal Flex™ is as clear as Polycarbonate filament. This unique feature makes Crystal Flex™ extremely suitable for printing light-transmitting objects.

Another great feature about Crystal Flex™ is its resilience and bendability. Crystal Flex™ is a very tough material and has a shore hardness of D65, which enables this filament to being bent up to 175% without causing white stress marks after bending.

Crystal Flex™ has a high interlayer adhesion, making it a really wonderful and easy-to-print filament. Crystal Flex™’s recommended printing temperature is between ~215° and ~240°C, with ~240°C as recommended temperature for best layer adhesion during printing at high speed. Crystal Flex™’s thermal stability is comparable with that of PLA (65° – 70°C).

Crystal Flex™’s water absorption is only 30% of that of ABS, meaning that there will be less evaporation and therefore prints are less likely to warp. Crystal Flex™ sticks well to ABS and PLA, which makes this 3D printer filament also suitable for multi-material prints. However, do keep in mind that Crystal Flex™ gets crumbly from Acetone. So it is recommended not to smooth your ABS/Crystal Flex™ multi-material prints afterwards with Acetone.

Crystal Flex™’s unique set of characteristics with respect to its high impact resistance, light emission and flexibility enables a whole new field of application for FFF/FDM desktop 3D printers. Crystal Flex™’s bendability and high impact strength allow the material being used for instance for hinges and other mechanical parts to be built into other, firmer and inflexible parts. The combination of being flexible and resilient make Crystal Flex™ also very suitable for creating belts and straps.

Basically Crystal Flex™ will come in handy for any object requiring flexibility, resilience, or light emission.

Crystal Flex™ is soluble in brake cleaner.

CrystalFlex™ - 1.75mm - Click Here

CrystalFlex™ - 2.85mm - Click Here

NOTE: To achieve optimal printing results, please refer to FormFutura's general print settings available here: Click here